Specification of Titanium Forgings

| Product Name | Titanium Forgings |

| Grade | GR1, GR2, GR5, GR5ELI, GR7, GR9, GR12, GR23, Ti-4Al-2V, Ti-4Al-1.5Mn. |

| Size | as your request |

| Standard | GB/T16598-1996, GIB2218-1994, GJB2220-1994, GJB2744-1996, GJB391-1987, GJB943-1900, ASTM B381-2005, ASTM F620-2002, AMS4924-2002, AMS4926-2001, AMS4928-2001, AMS4930-2001, AMS4965-2002, AN1S4966-2003, AMS4967-2001, ASM4973-2002, ASM4983-2002, ASN14985-2003, ASM4991-2002, MIL-F-83142-2000, BS2TA9: 1973, BS2TA13:1974, BS2TA24:1973, BSTA42: 1993, BSTA51: 1993, JISH4657-1998, DIN17864-1993, NFL14-602 1984, NFL14-604 1984, NFL14-612 1984 |

| Brand Name | Yesheng |

| Application | chemical industry, Aerospace, deep sea, military, medical, etc. |

| Feature | High corrosion resistance, low density, good thermal stability, High strength and light weight. |

| Technics | Forging Process |

| Surface | Annealed surface, Polished surface. |

| Packing | Export Standard Woodcase |

| MOQ | as your request |

| Payment terms | T/T, Western Union, PayPal. |

| Certificate | ISO 9001:2015; The third test report. |

| Delivery time | 10—25days according to the quantity and process of the product |

| Quality and test | Ingredient testing |

| Price Term: | CIF CNF/CFR FOB Ex-work |

For custom titanium products, contact us.

TITANIUM FORGINGS APPLICATION

Aerospace: Titanium is light in weight and high in strength, and is used in aircraft structural parts, engine parts, spacecraft structural parts, etc.

Deep sea: Titanium is corrosion-resistant, anti-oxidant, and high-strength. It is mainly used for processing deep-sea oil exploration equipment, ocean depth detection equipment, and ocean energy development equipment.

Military industry: It is widely used in the manufacture of key components of weapons and equipment, and can also be used to manufacture armor materials for tanks, armored vehicles and other equipment.

Medical devices: Titanium has excellent biocompatibility and good corrosion resistance. It is an ideal material for artificial bone brackets and medical devices. It is mainly used for artificial joints, human implants, and medical tools.

Chemical equipment: The corrosion resistance of titanium can be used to manufacture chemical reactors and reactor linings, sewage treatment equipment, and chemical storage tanks and other chemical equipment.

Advantages of Yeshengti Titanium Forgings

Precision Engineering:

Yeshengti's titanium forgings undergo meticulous engineering, ensuring dimensional accuracy and superior quality in each product. Precision is the hallmark of our forging expertise.

Corrosion Resistance:

Titanium's innate corrosion resistance is amplified in Yeshengti's forgings. This characteristic makes our titanium forgings ideal for applications in corrosive environments, ensuring longevity and performance.

Customization:

Yeshengti takes pride in offering customized solutions. Our Titanium Custom Forged Parts and other forgings can be tailored to specific dimensions and requirements, providing clients with optimal solutions for their unique applications.

Versatility:

From aerospace to chemical processing, Yeshengti's titanium forgings demonstrate versatility. Their adaptability to various industries underscores the diverse applications and advantages they bring to each sector.

Yeshengti Titanium Forging Company's commitment to precision, durability, and customization positions our titanium forgings as reliable components in critical industries, driving innovation and excellence in engineering.

Yeshengti titanium forgings capabilities

Material Grades: Forging companies work with diverse titanium grades, such as commercially pure grades (e.g., Gr2) known for formability, corrosion resistance, and biocompatibility, making them suitable for medical implants. Titanium alloys (e.g., Gr4, Gr5) provide higher strength and can undergo heat treatment for enhanced properties, ideal for aerospace and high-performance applications.

Part Size and Weight: Forging companies can produce titanium forgings ranging from small aerospace components weighing a few kilograms to large industrial parts weighing several hundred kilograms, depending on their equipment capabilities.

Surface Finish: Titanium forgings can achieve various surface finishes, from rough as-forged textures suitable for structural components to smooth machined finishes required for precision applications.

Heat Treatment: Certain titanium forgings can undergo heat treatment processes to modify their mechanical properties, such as increasing strength or improving fatigue resistance. This capability allows for tailored solutions to meet specific performance requirements in demanding environments.

Overall, titanium forgings combine the unique properties of titanium alloys with the precision and strength offered by forging processes, making them indispensable in applications requiring lightweight, durable, and high-performance components.

전문 지식을 갖춘 Yeshengti의 Titanium Cathode Rollers는 전기 도금 공정에서 탁월합니다. 이 단조품은 내식성과 높은 전도성을 제공하여 최적의 성능을 보장합니다.티타늄 음극 롤러 가격

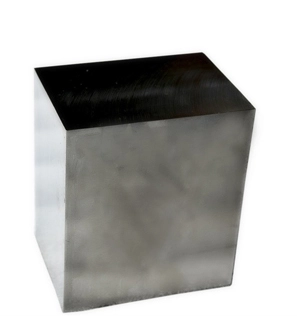

전문 지식을 갖춘 Yeshengti의 Titanium Cathode Rollers는 전기 도금 공정에서 탁월합니다. 이 단조품은 내식성과 높은 전도성을 제공하여 최적의 성능을 보장합니다.티타늄 음극 롤러 가격 Yeshengti의 전문 지식은 특정 산업 요구에 맞게 티타늄 맞춤 단조 부품 제작으로 확장됩니다. 이 단조품은 강도, 정밀도 및 사용자 정의 완벽한 조화를 제공합니다.티타늄 맞춤 단조 부품 가격

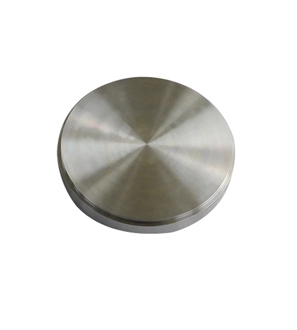

Yeshengti의 전문 지식은 특정 산업 요구에 맞게 티타늄 맞춤 단조 부품 제작으로 확장됩니다. 이 단조품은 강도, 정밀도 및 사용자 정의 완벽한 조화를 제공합니다.티타늄 맞춤 단조 부품 가격 티타늄 DiscProduct NameTitanium ForgingsGradeGR1,GR2,GR5,GR5ELI,GR7,GR9,GR12,GR23,Ti-4Al-2V, requestStandardGB/T16598-1996 Ti-4Al-1.5Mn.Sizeas, GIB2218-1994, GJB2220-1994, GJB27. ..티타늄 디스크 가격

티타늄 DiscProduct NameTitanium ForgingsGradeGR1,GR2,GR5,GR5ELI,GR7,GR9,GR12,GR23,Ti-4Al-2V, requestStandardGB/T16598-1996 Ti-4Al-1.5Mn.Sizeas, GIB2218-1994, GJB2220-1994, GJB27. ..티타늄 디스크 가격 Yeshengti의 티타늄 플랜지는 고압 환경에서 내구성을 재정의합니다. 석유 및 가스 산업에 이상적 인이 단조품은 우수한 내식성과 우수한 강도, ensur...티타늄 플랜지 가격

Yeshengti의 티타늄 플랜지는 고압 환경에서 내구성을 재정의합니다. 석유 및 가스 산업에 이상적 인이 단조품은 우수한 내식성과 우수한 강도, ensur...티타늄 플랜지 가격 Yeshengti의 티타늄 단조 반지는 강도와 정밀도의 원활한 조화를 제공합니다. 항공 우주 및 발전에 널리 사용되는 이러한 단조품은 구조적 무결성과 신뢰성을 제공합니다.티타늄 위조 반지 가격

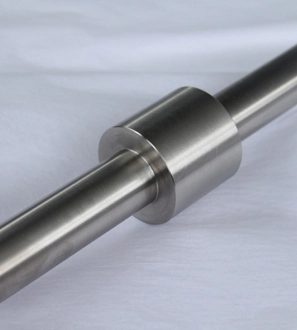

Yeshengti의 티타늄 단조 반지는 강도와 정밀도의 원활한 조화를 제공합니다. 항공 우주 및 발전에 널리 사용되는 이러한 단조품은 구조적 무결성과 신뢰성을 제공합니다.티타늄 위조 반지 가격 정밀도와 내구성을 위해 설계된 Yeshengti의 티타늄 샤프트는 항공 우주 및 기계 분야에서 응용 분야를 찾습니다. 이 단조품은 뛰어난 강도, 피로 저항 및 부식을 나타냅니다...티타늄 샤프트 가격

정밀도와 내구성을 위해 설계된 Yeshengti의 티타늄 샤프트는 항공 우주 및 기계 분야에서 응용 분야를 찾습니다. 이 단조품은 뛰어난 강도, 피로 저항 및 부식을 나타냅니다...티타늄 샤프트 가격 English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский